THE

MOST PORTABLE AND HANDY TOMOGRAPH FOR REINFORCED CONCRETE INSPECTION

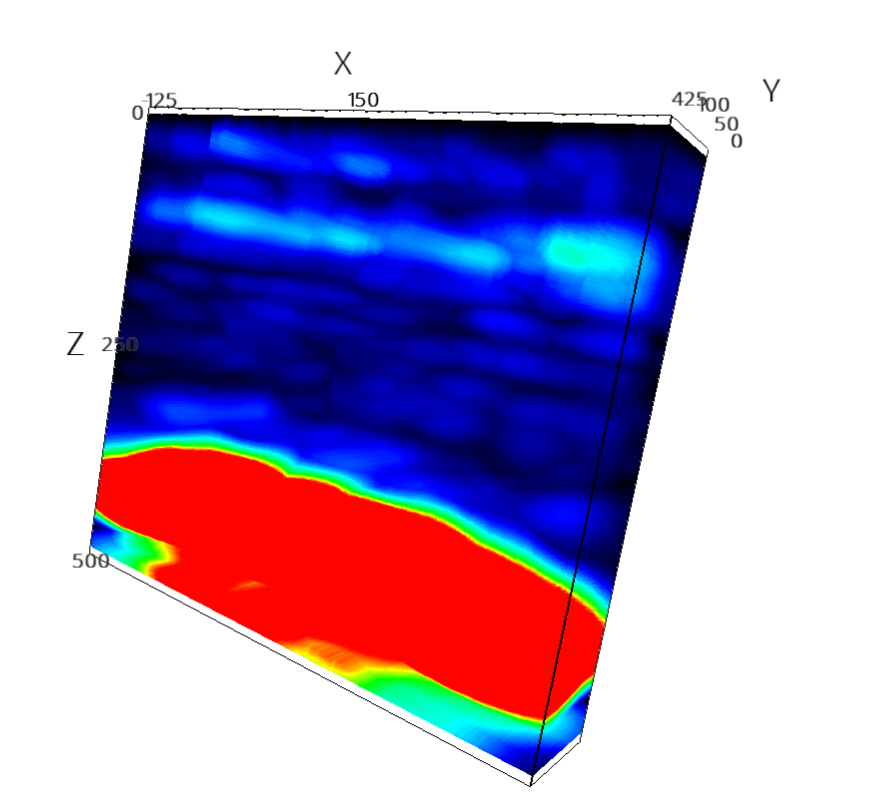

Real-time

B-scan image

? New generation of wear-proof DPC transducers

? Outstanding near-field resolution

? Optional Full-3D acquisition mode

Visualization

by INTROVIEW®

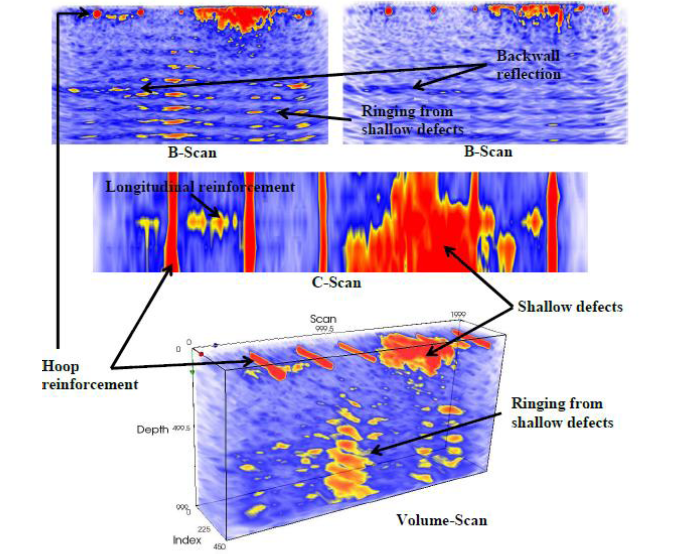

? Integral assessment by 3D imaging

? Novel crack sizing functionality

PRODUCT DESCRIPTION

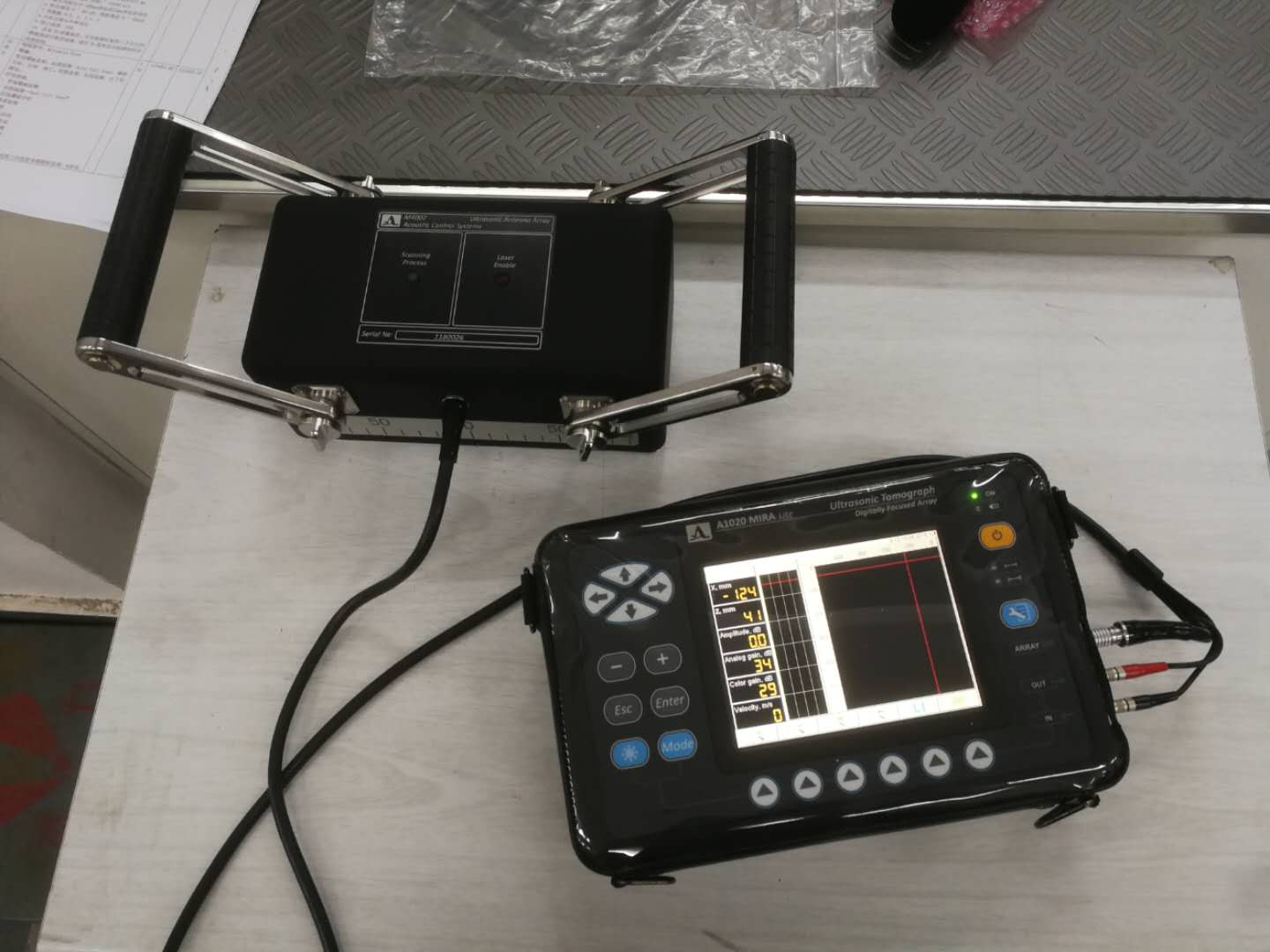

A1020 MIRA-lite is a low-frequency ultrasonic tomography system

for manual ultrasonic testing, 2D and 3D visualization and quality evaluation

of concrete and reinforced concrete structures.

The instrument is a hand-held lightweight low-frequency

ultrasonic device of general purpose. It is a fully autonomous system used for

acquisition, topographic processind and evaluation of pulse-echo ultrasonic

data. The sensor system contains a matrix antenna of 32 (8 blocks with 4

elements in each) low-frequency broadband transverse wave dry point contact

(DPC) transducers with ceramic wear-resistant tips for long-term couplant-free

operation on rough surfaces.

The A1020 MIRA-lite is dedicated for non-destructive testing

constructions made of concrete, reinforced concrete and stone with one-sided

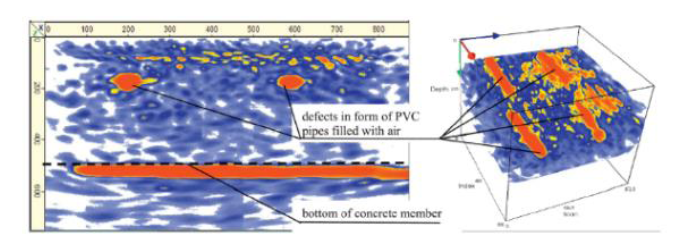

access. It allows estimation of material integrity by detection of local

inclusions, cavities, voids, delaminations, not grouted areas and cracks as

well as object thickness measure. Typical application fields of the system are reinforced-concrete

buildings, facilities, bridges, tunnels, highways, airdromes in construction

and in operation / maintenance. Further the instrument can be used in the

mining industry to evaluate the quality of the exploitable minerals.

The A1020 MIRA-lite allows quick and efficient testing of the

large objects with its three-dimensional visualization and documentation of the

inspection results by means of provided software INTROVIEW-CONCRETE by ACS (in

delivery volume).

APPLICATION

Inspection of concrete constructions up to 1200 mm thickness for

the purpose of evaluation of consistency of the construction.

Search for foreign inclusions, cavities, voids, delaminations,

leaks of filling and cracks in the concrete objects, reinforced concrete

objects and natural stone.

Search for plastic and metal pipes of a diameter more than 10 mm

in reinforced concrete.

Evaluation of condition of the channels with stressed

reinforcement in reinforced concrete bridges.

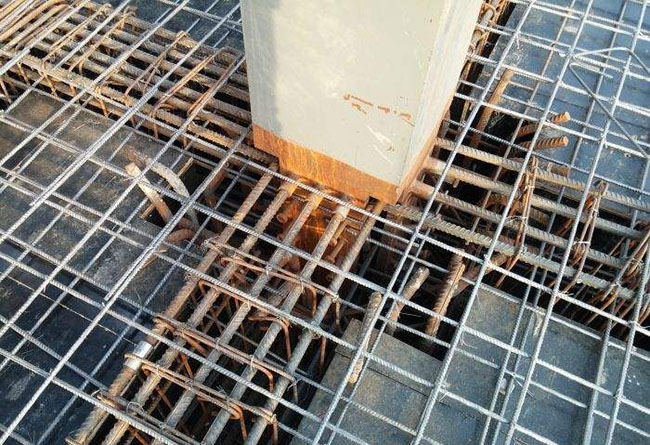

Inspection of understructures, columns, overhead covers in

cast-in-place constructions to detect voids and leaks of filling.

Search for voids and cavities back of liner plates of

underground and railway tunnels.

Inspection of refractory blocks of the glass blowing furnace.

Estimation of the thickness of the concrete cover and depth of

coverage reinforcement.

Thickness measurement of the testing object at one-sided access.

Detailed registration of the results obtained.

Download

相關(guān)標(biāo)簽

ACSYS,ACS,A1020 MIRA Lite,A1020 MIRA,A1020,T/CECS XXX-202X, JGJ/T485-2019,江蘇省DB32/T 3754-2020,DB34/T 5072-2017,DB37/T 5106-2018,DG/TJ 08-2252-2018,DB13(J)/T 8327-2019,DBJ/T-199-2020

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717